Powder quantitative packaging machine adopts frequency conversion speed regulation function, electronic automatic metering technology, and is controlled by PLC program, which can completely solve the problem of one-time filling of fine and ultra-fine powder, with accurate measurement and no dust.

【Scope of application】: Powder packaging machine is suitable for automatic quantitative filling of materials in non-metal, chemical, building materials, environmental protection, and other industries. Such as dyes, pigments, cement, fly ash, dry mortar, talc, calcium carbonate, etc.

【Applicable materials】: Powder packaging machine is suitable for titanium dioxide, carbon black, dry powder mortar, kaolin, PVC, plastic, calcium carbonate, talc, medicine, chemical industry, feed, food, and other industries.

【Product introduction】: The bag making, sealing, and filling of the powder packaging machine are relatively independent systems. The two systems are coordinated and linked through mechanical linkage and programmable logic controller (PLC). Therefore, it can be adapted to different packaging objects and external dimensions of packaging bags.

How does the powder packaging machine work?

The performance characteristics of the packaging machine:

- 1. Simplifying the transmission system, greatly reduce the failure rate, and reduce the maintenance cost of the enterprise.

- 2. Increase production and reduce costs. It can improve production technology, improve product output and quality, and effectively save costs and achieve profitability.

- 3. Realize the software of the control and improve the function.

- 4. Through the functions of torque compensation, stall prevention, and restart, the non-trip operation is realized; the quality of the produced products is stable and the efficiency is improved.

Structure of the packaging machine

Packaging machines mainly include packaging machines, filling machines, sealing machines, coding machines, balers, vacuum machines, shrinking machines, vacuum packaging machines, weighing packaging machines, etc.

Daily maintenance of powder packaging machine

Valve port type powder quantitative packaging machine

Micro Powder Packing Machine

Powder filling machine

- 1. The vacuum packaging machine should be used in an environment where the temperature is -10℃-50℃, the relative humidity is not more than 85%, and there is no corrosive gas in the surrounding air, no dust, and no explosive danger.

- 2. To ensure the normal operation of the vacuum pump for the vacuum packaging machine, the vacuum pump motor is not allowed to reverse. The oil level should be checked frequently. The normal oil level is 1/2-3/4 of the oil window.

- 3. The impurity filter should be disassembled and washed frequently usually every 1-2 months.

- 4. After working continuously for 2-3 months, the back cover 30 should be opened to add lubricating oil to the sliding parts and switch bumps, and the connecting activities on the heating rod should be lubricated according to the usage conditions.

- 5. Regularly check the triple parts 24 of decompression, filtration, and oil mist to ensure that there is oil in the oil mist and oil cup, and there is no water in the filter cup.

- 6. The heating strip and the silicone strip should be kept clean, and no foreign matter should be stuck, so as not to affect the sealing quality.

- 7. On the heating rod, the second layer of the sticky paste under the heating sheet plays a role and should be replaced in time when it is damaged to avoid a short circuit.

- 8. The working air source and inflation air source are provided by the user. The working pressure of the vacuum packaging machine has been set to 0.3MPa, which is more appropriate. Do not adjust it too much unless there are special circumstances.

- 9. The vacuum packaging machine is not allowed to be tilted and impacted during the handling process, and it is not allowed to be tipped for handling.

- 10. The vacuum packaging machine must have a reliable grounding device during installation.

- 11. It is strictly forbidden to put your hand under the heating rod to prevent injury. In case of emergency, cut off the power immediately.

- 12. When working, first ventilate and then power on, and when shutting down, first power off and then cut off the gas.

Technical parameters of packaging machine

| Type | Bag weight | Accuracy | Power | Filling speed | Air consumption | Dimension(W*L*H) |

| CBF-159A | 3-50 kg | ±0.2~0.5% | 380V, 50HZ, 4KW | 3-5 bags/min, (25kg) | P≥0.6Mpa, Q≥0.4m³/min | 800x1400x1850mm |

| CBF-159B | 1-60 kg | ±0.1~0.3% | 380V, 50HZ, 8KW | 3-5 bags/min, (25kg) | P≥0.6Mpa, Q≥0.4m³/min | 850x1500x2155mm |

| CBC-200C | 1-50 kg | ±0.2~0.5% | 380V, 50HZ, 3KW | 3-5 bags/min, (25kg) | P≥0.6Mpa, Q≥0.4m³/min | 3300x2000x2755mm |

| CBC-1000D | 1-2000 kg | ±0.2~0.5% | 380V, 50HZ, 3KW | 7-10 bags/min, (1ton) | P≥0.6Mpa, Q≥0.4m³/min | 880x1800x2500mm |

Valve type powder quantitative packaging machine

Product introduction of valve type powder quantitative packaging machine

GBF-159A valve port type vacuum powder quantitative packaging machine is fed by a variable speed screw, adopts the negative pressure suction technology in the bag, and has functions such as automatic dust recovery.

It is mainly designed for the ultra-fine powder industry with light specific gravity, high bulk density, strong fluidity, strong air affinity, ultra-fine particle size, high gas content and cannot be packaged at one time, and strictly control the production of dust escape on the production site.

The site environment is clean.

This model adopts frequency conversion speed regulation function, electronic automatic metering technology, and is controlled by PLC program, which can completely solve the filling of ultrafine powder at one time, with accurate measurement and no dust.

Widely used in carbon black, nano calcium carbonate, ultrafine talc, kaolin, silicon dioxide, stabilizer, stearic acid, corn starch, bentonite, and other ultrafine powders.

Valve type powder quantitative packaging machine working principle

This machine adopts PLC automatic control system, automatic weighing, to achieve the purpose of quantitative, the machine can be widely used in the quantitative packaging of carbon black, talc powder, calcite powder, heavy calcium powder and other powders.

Valve type powder quantitative packaging machine performance characteristics

The valve port type powder quantitative packaging machine is fed by variable speed blades and adopts silo air return technology. It is mainly designed for the coarse powder industry with large density, small volume and large production capacity. It adopts frequency conversion speed regulation function and electronic automatic metering technology. Program control, automatic operation in the whole process, with fast packaging speed, accurate measurement, no dust and so on. Widely used in heavy calcium carbonate, talc, flour, cement, resin, putty powder, stearic acid and other powders.

Related Products

Coarse, Fine, Ultrafine Powder Grinding Mills

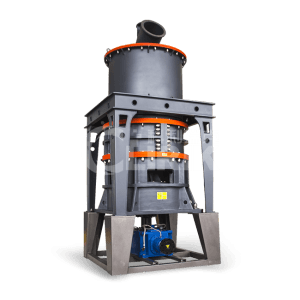

CLUM Ultrafine Powder Vertical Roller Mill

CLUM ultra-fine powder vertical roller mill is mainly suitable for the deep processing of ultra-fine and large-scale powder of non-metallic minerals such as calcite, marble, limestone, talc, barite, brucite, quicklime, gypsum, slag, phosphate, etc.

Capacity: 0.5-45t/h

Finished fineness: 200-3000 mesh

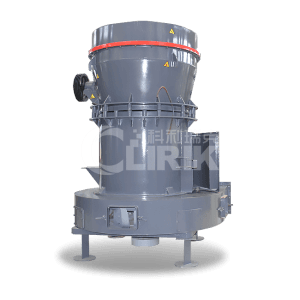

HGM Ultrafine Powder Grinding Mill

HGM Ultrafine Powder Grinding Mill also called ultrafine pulverizer, micro powder grinding mill, limestone grinding mill, calcium carbonate grinding mill. HGM ultrafine powder grinding mill is mainly suitable for superfine powder processing.

Capacity: 0.5-45t/h

Finished fineness: 100-3000 mesh

YGM Raymond Roller Grinding Mill

YGM Raymond roller grinding mill is mainly suitable for grinding and processing metallurgy, building materials, chemical industry, mining, and other mineral products.

Capacity: 1.5-40t/h

Finished fineness: 80-600 mesh

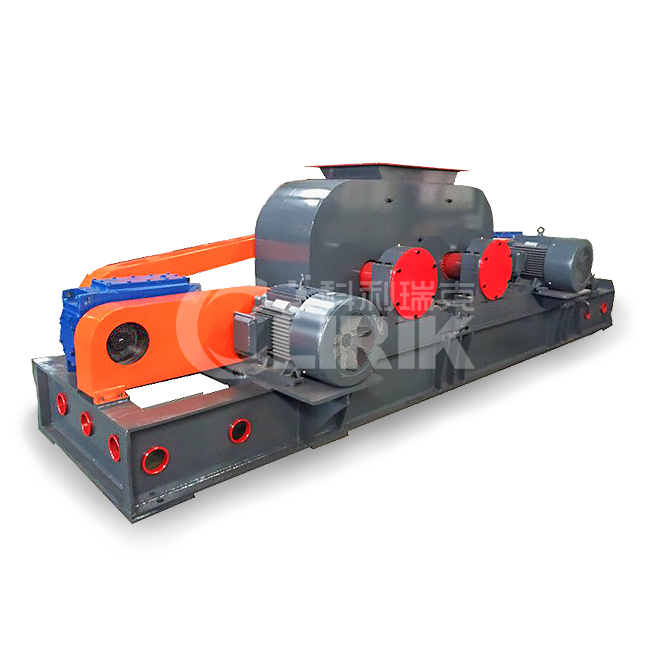

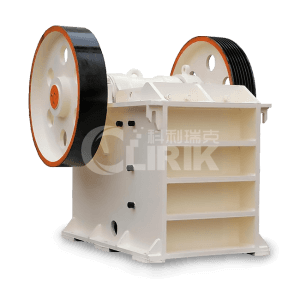

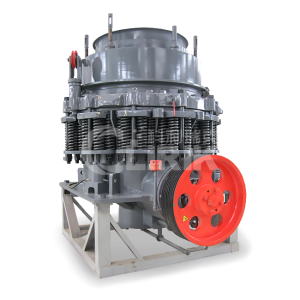

Stone Crushers

Stone Crushing Plant

Application range: sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Material: river pebble, granite, basalt, iron ore, limestone, quartz stone, diabase, etc.

Feed particle size: ≤480mm

Production capacity: 1-140t/h

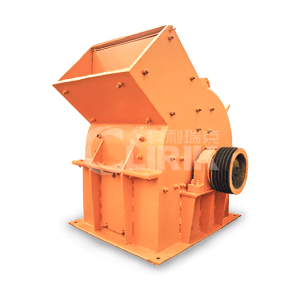

Application range: sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Material: river pebble, granite, basalt, iron ore, limestone, quartz stone, diabase, etc.

Feed particle size: ≤100mm

Production capacity: 35-132t/h

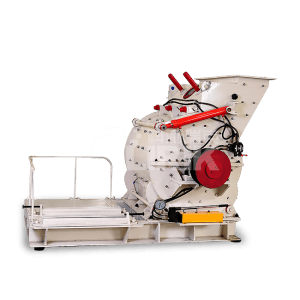

Application range: sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Material: river pebble, granite, basalt, iron ore, limestone, quartz stone, diabase, etc.

Capacity: 15-60t/h

Finished fineness: ≤3mm

Application range: river pebble, granite, basalt, iron ore, limestone, quartzite, diabase, etc.

Materials: sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Feed particle size: 76-290 mm

Production capacity: 120-430 t/h

Application range: sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Materials: River pebble, granite, basalt, iron ore, limestone, quartzite, diabase, etc.

Motor power: 30-400 kw

Production capacity: 10-550 t/h