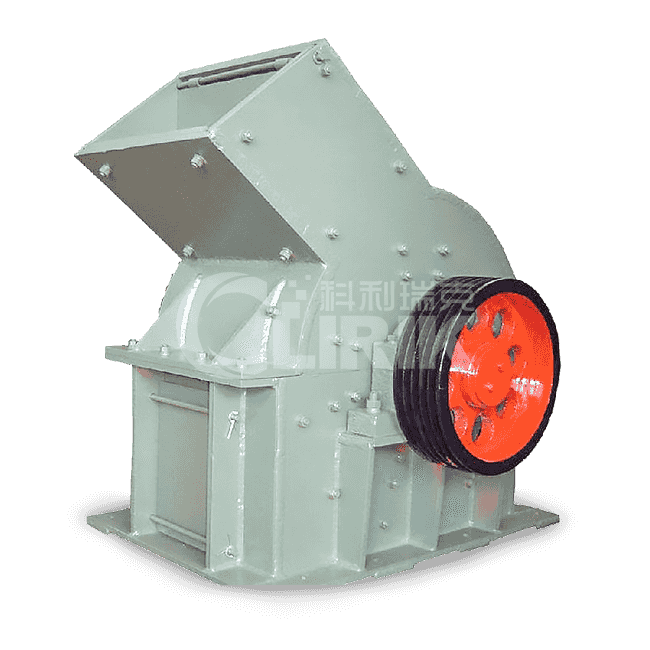

Hammer crusher is mainly used in metallurgy, mining, cement, chemical industry, refractory materials and ceramics, and other industrial sectors. The medium-hard ore is subjected to coarse crushing, medium crushing, and fine crushing.

Application range: sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Material: river pebble, granite, basalt, iron ore, limestone, quartz stone, diabase, etc.

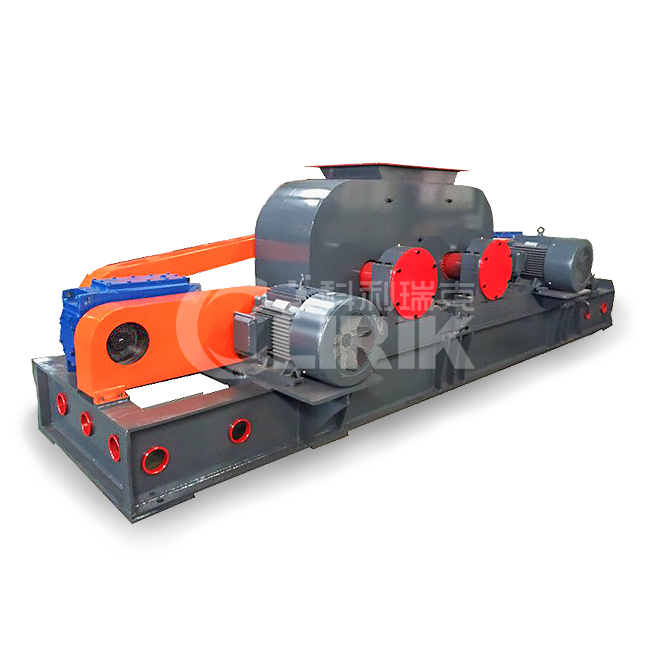

Feed particle size: ≤100mm

Production capacity: 35-132t/h

Features of Hammer Crusher

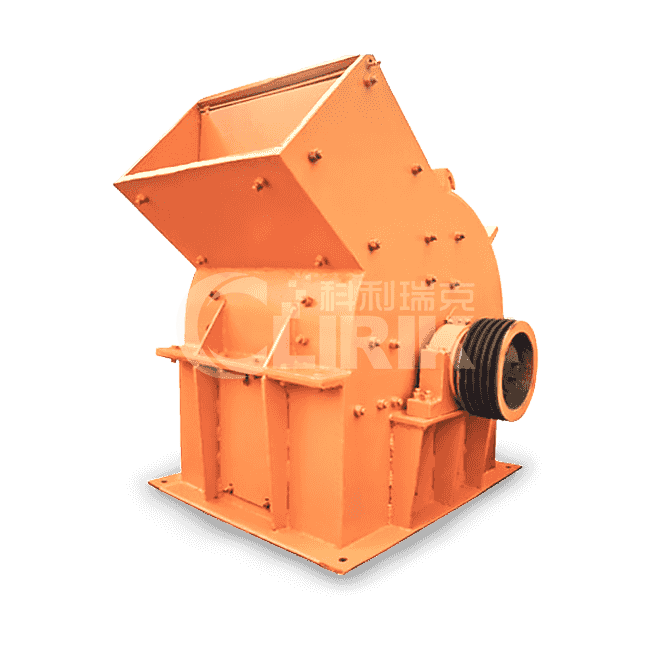

Hammer Crusher

Stone Hammer Crusher

Hammer crusher structure diagram There are several rows of hanging hammer bodies installed on the main shaft of the crusher. A pin shaft runs through the pinhole in its circumference, and the hammer is hinged between each row of hanging hammer bodies with the pin shaft.

After the hammer is worn, the working surface can be replaced. There are two trapped pin holes on the hanging hammer body. The distance from the center of the pinhole to the center of the rotation axis is different, which is used to adjust the gap between the hammer and the grate.

In order to prevent the hanging hammer body and the hammer from moving in the platinum direction, the two ends of the hanging hammer body are fixed with pressing hammer discs and locking nuts.

It is supported on rolling bearings at both ends, and the bearings are fixed on the casing with bolts. The main shaft and motor are directly connected with elastic coupling. To make the rotor run smoothly, a flywheel is mounted on one end of the main shaft.

The arc-shaped discharge screen is installed under the rotor, the two ends of the grate are installed on the beam, and the grate outside the member is pressed by the pressing plate, and the arrangement direction of the grate is perpendicular to the movement direction of the rotor.

The grate gap is formed by the protruding part in the middle of the grate. In order to facilitate material discharge. The gap of the grate gradually expands downward, and at the same time, it is inclined to the rotation direction of the rotor.

Performance Advantage of Hammer Crusher

Hammer Crusher Features:

1. The bearing boxes of the hammer mill are all made of steel castings, and each shaft box is fixed with four screws. Change the major safety hazard of bearing box wear caused by loose screws of the previous generation of hammer crusher products. Make the same equipment more scientific and more applicable.

2. The crushing ratio is large, generally 10-25, and the highest one can reach 50. High production capacity, uniform product, less excessive phenomenon, low energy consumption per unit product, simple structure, light equipment quality, easy operation and maintenance, etc. From the research of energy consumption and efficiency, the equipment has high crushing and grinding efficiency and low power consumption, which greatly improves the production efficiency and reduces the production cost of materials.

3. The hammer mill adopts two sets of rotors connected in series with each other to transport the material through the conveyor to the feeding port of the hammer mill. The materials crushed by the upper rotor in the hammer crusher cavity enter immediately. The hammer head of the rapidly rotating lower rotor is crushed again, and the materials in the crushing chamber of the hammer crusher collide rapidly and crush each other, forming the effect of hammer powder and crushing, and then directly discharged from the discharge port to form the discharge particle size. Material particles smaller than 3 mm.

Structure and Composition of Hammer Crusher

The structure of hammer crusher:

The rotor is the "heart" of the hammer crusher, and it is also the strictly accepted part of the hammer crusher, which plays a vital role in the work. That's why CLIRIK Technologies has developed and produced heavy-duty rotors with robust construction for a higher moment of inertia. High wear-resistant materials and excellent crushing cavities make the crusher perform well. The hammer crusher has an improved adjustment device and is more convenient to operate. The three-chamber crushing of the hammer crusher is extraordinary in fine crushing and ultra-fine crushing operations. The two-chamber crushing of the hammer crusher can simplify the process flow during the coarse and medium crushing operations.

Working Principle of Hammer Crusher

How Hammer Crusher Works?

The main working part is the rotor with the hammer. The rotor consists of a main shaft, a disc, a pin and a hammer. The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feeding port, and is crushed by the impact, impact, shearing and grinding of the high-speed hammer. In the lower part of the rotor, there is a sieve plate, and the particle size smaller than the sieve hole size in the crushed material is discharged through the sieve plate, and the coarse particle size larger than the sieve hole size is left in the sieve plate.

Technical Parameter of Hammer Crusher

| ModelModel | Feeding particle size (mm) | Discharge particle size (mm) | Production capacity (m³/h) | Motor power (kw) | Total weight (t) | Dimensions (L×W×H)(mm) |

|---|---|---|---|---|---|---|

| PC400×300 | <100 | 0-10 | 3-8 | 11 | 0.5 | 855×795×860 |

| PC600×400 | <220 | 0-20 | 8-15 | 18.5-22 | 1.6 | 1150×1095×1230 |

| PC800×600 | <350 | 0-25 | 15-45 | 45 | 4 | 2360×1490×1415 |

| PC1000×800 | <400 | 0-25 | 40-60 | 75 | 6.5 | 3072×1720×2121 |