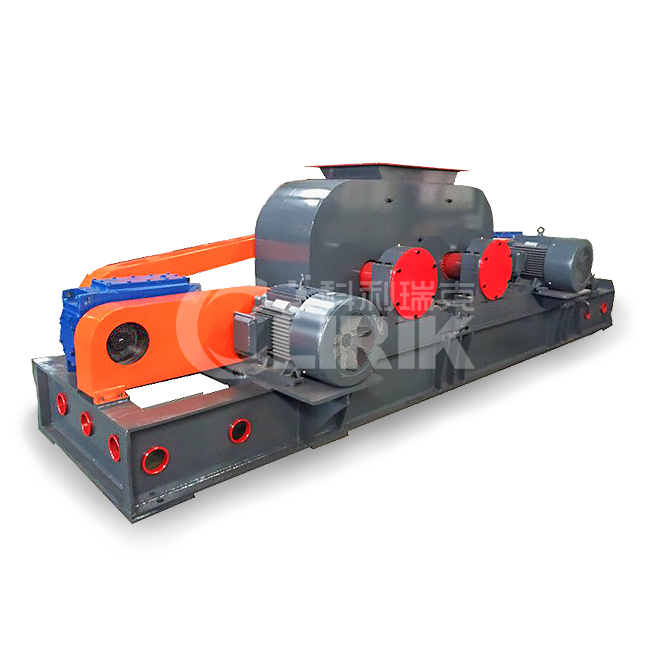

Jaw crushers are mainly used in metallurgy, mining, cement, chemical industry, refractory materials and ceramics, and other industrial sectors. They are widely used in highway construction, water conservancy projects, construction gravel, machine-made sand processing, and other fields. The medium-hard ore is subjected to coarse crushing, medium crushing, and fine crushing.

Application range: sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Material: river pebble, granite, basalt, iron ore, limestone, quartz stone, diabase, etc.

Feed particle size: ≤480mm

Production capacity: 1-140t/h

Features of Jaw Crusher

Jaw Crusher

Stone Crusher

small jaw crusher

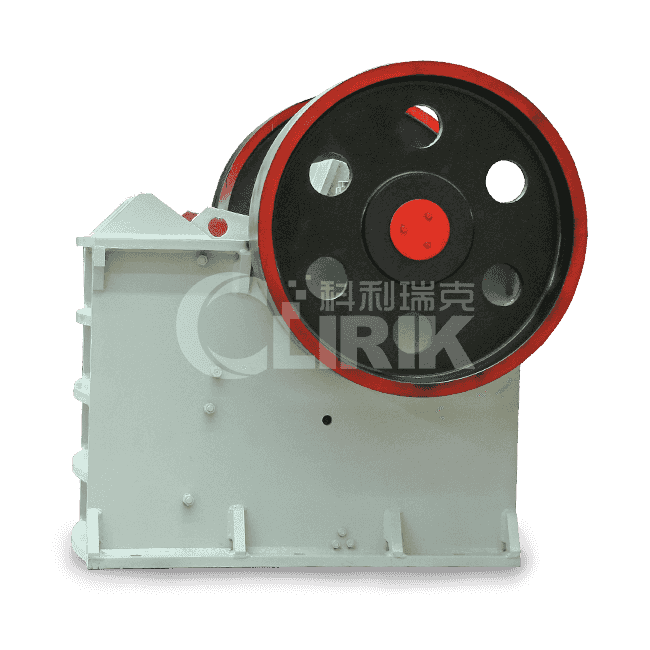

Jaw crusher is early crushing equipment, because of its simple structure, firmness, reliable operation, easy maintenance and repair, and relatively low production and construction costs.

Therefore, it is still widely used in metallurgy, chemical industry, building materials, electricity, electricity, etc. In industrial sectors such as transportation, it is used for coarse, medium, and fine crushing of various ores and rocks with a compressive strength of 147-245MPa.

In recent years, our factory has specially developed a powerful jaw crusher in order to meet the needs of metallurgy, mining, construction, and other industrial sectors to crush high-strength, high-hardness micro-carbon ferrochromium.

The jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials and is widely used in mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.

The high compressive strength of the crushed material is 320MPa. The jaw crusher has a large crushing ratio, uniform product size, simple structure, reliable operation, easy maintenance, and low operating cost.

Jaw Crusher Advantages

1. The crushing cavity is deep and has no dead zone, which improves the feeding capacity and output of the jaw crusher.

2. Its crushing ratio is large and the product particle size is uniform.

3. The gasket-type discharge port adjustment device is reliable and convenient, and the adjustment range is large, which increases the flexibility of the equipment.

4. The lubrication system is safe and reliable, the parts are easily replaced, and the maintenance workload is small.

5. Simple structure, reliable work, and low operating cost.

6. Equipment energy saving: stand-alone energy-saving 15% to 30%, system energy saving more than double.

7. The adjustment range of the discharge port is large, which can meet the requirements of different users.

8. Low noise and less dust.

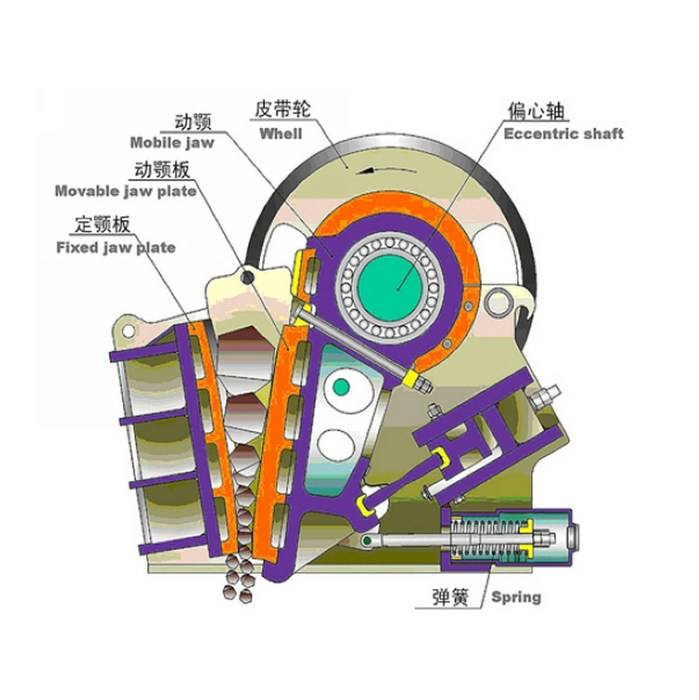

Structure and Composition of Jaw Crusher

The structure of the jaw crusher is mainly composed of a frame, an eccentric shaft, a large pulley, a flywheel, a movable jaw, a side guard, a bracket, a back seat of the bracket, a clearance adjustment screw, a return spring, a fixed jaw, and a movable jaw. The toggle plate also plays an insurance role.

Matters needing attention in the work of jaw crusher

1. Before using the jaw crusher, it is necessary to check whether there are foreign objects in the crushing cavity. When there are some foreign objects, it must be cleaned up in time before starting the machine. Otherwise, the motor will be damaged due to excessive load during startup.

2. What the jaw crusher is afraid of is that the feeding amount is not uniform during the feeding process, especially when the feeding amount is suddenly increased, the motor will be burned out due to excessive load.

3. When it is necessary to stop production, first stop the feeding and then stop the operation of the jaw crusher. Because if the machine is stopped first, there will be a large amount of unprocessed ore material in the machine, which will cause damage to the machine parts, and will overload the machine when it is restarted.

4. When using the jaw crusher for production, it is necessary to timely find out whether the machine has abnormal noise or other abnormal conditions. After the discovery, the cause should be detected and repaired in time, and the machine should not be allowed to work sick.

Working Principle of Jaw Crusher

The motor drives the belt and pulley and moves the movable jaw up and down through the eccentric shaft.

When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw to approach the fixed jaw.

At the same time, the material is crushed or split. crushing, to achieve the purpose of crushing (the price of the crusher); when the movable jaw goes down, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw leaves the fixed jaw under the action of the tie rod and the spring, and the crushed material is removed from the fixed jaw at this time.

Discharge from the lower opening of the crushing chamber.

With the continuous rotation of the motor, the crushing jaws perform periodic motions to crush and discharge materials to achieve mass production.

Technical Parameter

| Model | Inlet Size (mm) | Feed Particle Size (mm) | Discharge Port Adjustment Range (mm) | Power (KW) | Input Capacity (t/h) |

|---|---|---|---|---|---|

| PE150x250 | 150x250 | 125 | 10-40 | 5.5-7.5 | 1-5 |

| PE200x350 | 200x350 | 125 | 15-40 | 7.5-11 | 5-16 |

| PE250x400 | 250x400 | 210 | 20-60 | 15-18.5 | 5-20 |

| PE400x600 | 400x600 | 350 | 40-100 | 30-37 | 15-60 |

| PE500x750 | 500x750 | 425 | 50-100 | 45-55 | 40-100 |

| PE600x900 | 600x900 | 480 | 65-160 | 55-75 | 60-140 |

| PEX250x350 | 250x350 | 210 | ≤12 | 15-18.5 | 5-10 |

| PEX250x1000 | 250x1000 | 210 | 25-60 | 30-37 | 16-50 |

| PEX250x1200 | 250x1200 | 210 | 25-60 | 37-45 | 20-60 |

| PEX300x1300 | 300x1300 | 250 | 25-105 | 75 | 20-90 |