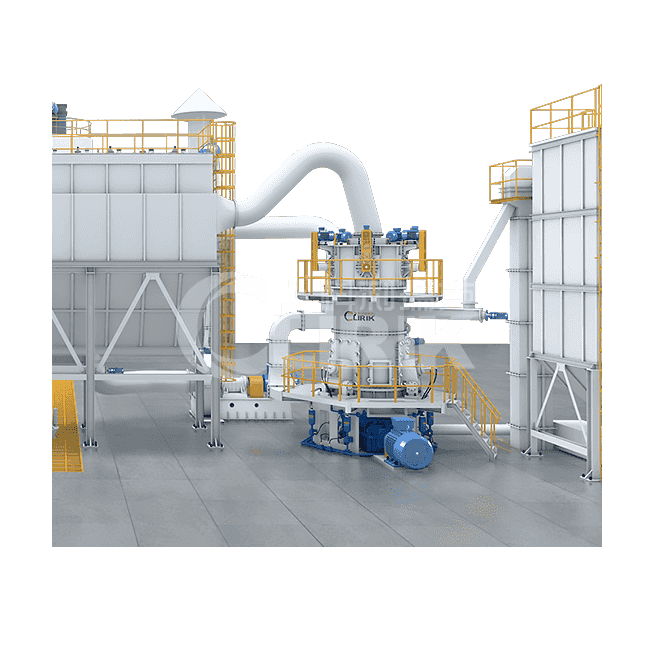

CLUM ultrafine powder vertical roller mill is mainly suitable for the deep processing of ultra-fine and large-scale powder of non-metallic minerals such as calcite, marble, limestone, talc, barite, brucite, quicklime, gypsum, slag, phosphate, etc.

Application range: cement ultrafine powder processing, calcite processing, barite, grinding processing

Material: calcite, marble, limestone, talc, barite, brucite, quicklime, gypsum, slag, phosphate and other non-metallic minerals

Capacity: 0.5-45t/h

Finished fineness: 200-3000 mesh

Features

Features

Ultrafine Grinding Mill

CLUM Ultrafine Vertical Grinding MIll

Vertical Roller Grinding Mill

With the rapid development of society and economy, in the field of ultra-fine powder processing, in the face of more and more application requirements for ultra-fine powder, traditional ultra-fine powder processing equipment has been difficult to meet market demand due to its generally low production capacity. Low production capacity has seriously restricted the development of modern ultra-fine powder processing enterprises.

In response to the current market demand, Shanghai CLIRIK Machinery combined with years of experience in the production of pulverizers introduced ultra-fine vertical grinding technology from Taiwan and Germany and designed and developed a set of grinding powder.

CLUM series ultrafine powder vertical grinding mill, a new type of ultra-fine grinding equipment integrating grading, conveying, secondary powder selection, and finished product packaging, the product fineness can reach 400-3000 mesh, breaking through the low production capacity of ultra-fine powder processing.

After 5 years of hard work, CLIRIK Ultrafine Vertical Grinding Mill has built 30 ultrafine powder production lines around the world.

CLUM series ultrafine powder vertical roller grinding mill can be widely used in chemical, metallurgy, non-metallic ores, and other industries, especially in the field of ultra-fine grinding of white non-metallic ores. Rubber, PVC, ink, and other industries provide high-quality fillers and additives.

It can be widely used in large-scale ultra-fine dry powder processing of non-metallic minerals such as calcite, marble, limestone, dolomite, barite, talc, kaolin, dolomite, wollastonite, gypsum, feldspar, and pyrophyllite.

Performance Advantages

Performance Advantages

1. Energy-efficient. The case of the same fineness of finished products and the same motor power, the output is more than double that of jet mill, stirring mill, and ball mill.

2. Long service life of wearing parts. Grinding rollers and grinding rings are forged with special materials, which greatly improves the utilization. Generally, it can last for more than one year. When processing calcium carbonate and calcite, the service life can reach 2-5 years.

3. High safety and reliability. Because there is no rolling bearing and no screw in the grinding chamber, there is no problem that the bearing and its seals are easily damaged, and there is no problem that the screw is easy to loosen and damage the machine.

4. Environmentally friendly and clean. The pulse dust collector is used to capture dust, and the muffler is used to reduce noise, which is environmentally friendly and clean.

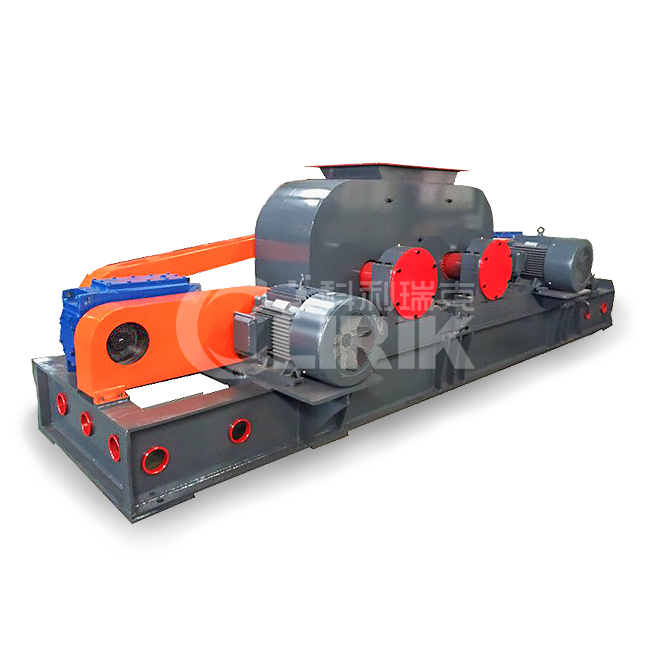

Structure and Composition

Structure and Composition

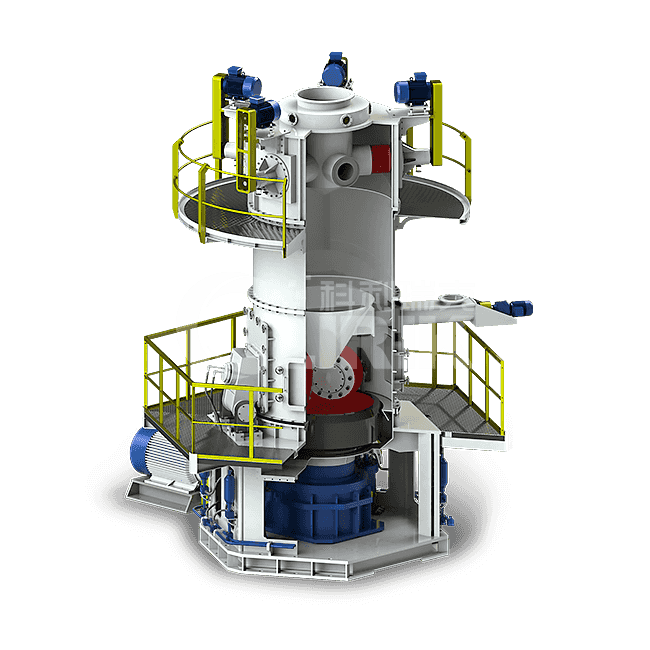

CLUM series ultrafine powder vertical roller grinding mill is mainly composed of electric motor, reducer, grinding wheel device, grinding disc device, pressurizing device, powder separator, feeding device, oil station, main engine, electric control system and other parts.

1. Grinding wheel device: the main part of the material to be rolled, without power output, it operates passively due to the frictional force in contact with the material.

2. Grinding disc device: The grinding area of the material is connected to the reducer and rotates by itself.

3. Pressurizing device: control the gap between the grinding wheel and the grinding disc to ensure the grinding wheel pressure during the grinding process.

4. Powder Separator: The multi-head powder separation structure uses the principle of rotating centrifugal force to realize the fine powder screening and filtration work in continuous production. It is an efficient and energy-saving powder separation device.

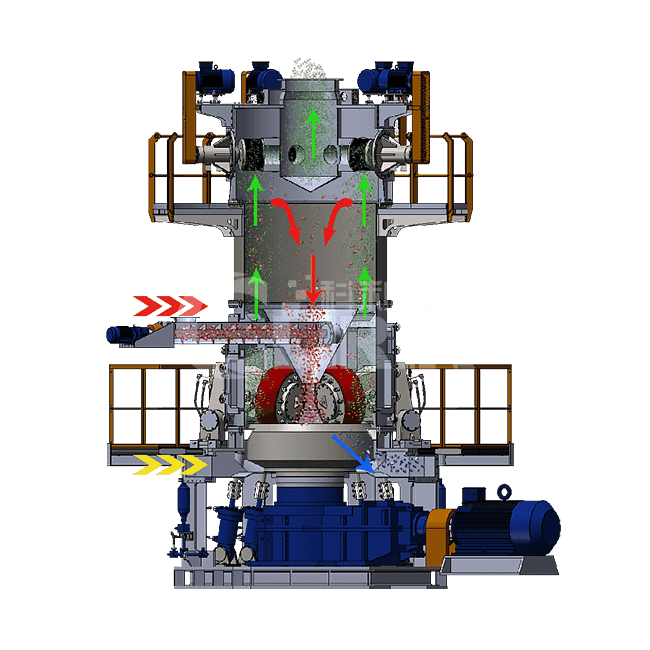

Working Principle

Working Principle

The motor of the main machine drives the grinding disc to rotate through the reducer.

At the same time, the air produced by the high-pressure fan enters the main machine from the tuyere.

The material is fed into the main machine of the vertical mill through the feeding screw and falls into the center of the grinding disc.

Under the action of the centrifuge, the material is scattered from the center of the grinding disc to the surrounding.

When it passes through the roller table area on the grinding disc, the large material is directly crushed by the pressure of the roller, and the small particle is pressed and then subjected to particle grinding to further pulverize until it becomes powder.

The powdered material continues to move to the edge of the grinding disc until it is taken away by the strong airflow at the air inlet.

When the material in the airflow passes through the upper separator, the coarse particles fall back into the grinding disc under the centrifugal force generated by the high-speed rotating impeller.

After grinding, the qualified powder passes through the powder selection system with the airflow and is collected by the dust collector, which is the finished product.

Technical Parameter

Technical Parameter

| Model | CLUM1425 | CLUM1632 | CLUM1736 |

|---|---|---|---|

| Turntable Diameter (mm) | 1400 | 1600 | 1700 |

| Number of Rollers ( pieces) | 3 | 3 | 3 |

| Number of Classifier (prices ) | 6 | 6 | 8 |

| Power of Classifier (kW) | 6x15 | 6x22 | 8x22 |

| Main Unit Power (kW) | 220-250 | 315-355 | 355-410 |

| Blower power (kW) | 180-200 | 250-280 | 325-355 |

| Feed Size (mm) | <10mm | <10mm | <10mm |

| Moisture of Feeding Material | <3% | <3% | <3% |

| Less than 2 μ m=30% output (t/h) | 9-12 | 12-16 | 14-1 |

| Less than 2 μ m=45% output (t/h) | 5.5-7.5 | 7-9 | 10-12 |

| Less than 2 μ m=60% output (t/h) | 3-4 | / | / |

Raw material: Take the production of calcite as an example

Particle size distribution: measured with a MALVERN3000 laser diffraction particle size analyzer from MALVERN, UK