Calcium carbonate powder is widely used in various fields. According to the different particle size of its powder, its application in different fields is also different. It is generally processed by a calcium carbonate mill or a whole calcium carbonate grinding plant

Limestone, marble, and calcite are common raw materials for calcium carbonate powder processing. So how does the hard stone become calcium carbonate powder?

Calcium carbonate powder grinding plant process

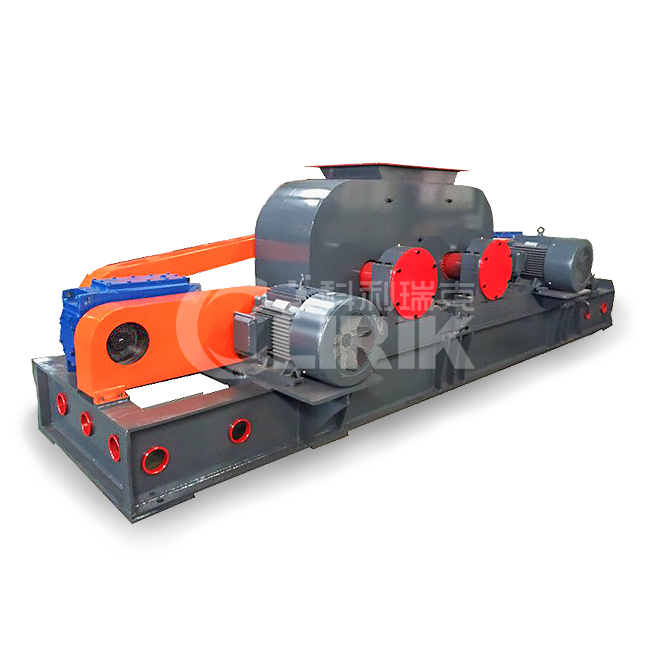

1. Crushing: Usually calcium carbonate processing usually has a large size. Because of the limited size of the input opening, it is impossible to be used for grinding. Such a large stone can be crushed into small pieces. Therefore, the crushing equipment on the calcium carbonate production line is generally recommended to choose a hammer crusher or a small jaw crusher.

2. Lifting: The opening of the calcium carbonate mill is usually at the top of the frame, so the raw materials must be lifted to the top of the machine for feeding. Bucket elevator is a better equipment with a small footprint to ensure smooth feeding.

3. Grinding: The grinding process is the core component of the entire calcium carbonate grinding production line. It usually includes calcium carbonate grinders, analyzers, electromagnetic vibrating feeders, powder separators, etc., along with the role of rollers, Grind the material to a high degree of fineness until it is discharged.

4. Dust removal: This is the last step of the calcium carbonate grinding production line. The grinding production not only causes pollution but also harms the health of workers. Therefore, we are equipped with a high-tech dust removal system to filter out more than 95% of the dust. The dust removal effect Significantly.

How to choose calcium carbonate grinding mill?

Different fineness of calcium carbonate powder requires different processing equipment. The following is the calcium carbonate mill to choose according to the discharge particle size:

HGM micro powder grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM ultrafine vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

For the choice of calcium carbonate mill, it is generally recommended to choose Raymond mill, because the powder produced by this equipment has a particle size of less than 325 mesh, which can fully meet the demand for calcium carbonate powder in the market, but there is also a need for finer powder For calcium carbonate powder with particle size, HGM micro powder grinding mill or CLUM ultra-fine grinding mill can be selected to meet customer needs. The particle size of the powder can reach 3000 mesh.

HGM micro powder grinding mill

HGM micro powder grinding mill is used for 200-2500 mesh calcium carbonate powder grinding plant

| Model | HGM80 | HGM90 | HGM100 | HGM100A | HGM125 |

| Ring Diameter(mm) | 800 | 930 | 1035 | 1035 | 1300 |

| Ring Number (PCS) | 3 | 3-4 | 3 | 4 | 4 |

| Roller Number(PCS) | 21 | 24-32 | 27 | 34-36 | 40-44 |

| Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 180-200 | 135-155 |

| Input Size (mm) | ≤20 | ||||

| Finished Size (um) | 5-47(325-2500) | ||||

| Capacity (t/h) | 0.5-4.5 | 0.6-6.5 | 0.7-7 | 1-8.5 | 1.5-12 |

| Outlet Size L*W*H (m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 18*4.6*8.6 | 14*9*10.25 |

| Motor powder (KW) | 145-165 | 185-204 | 263 | 263-290 | 380-430 |

YGM Raymond mill

YGM Raymond mill is used for 50-325 mesh calcium carbonate powder grinding plant

| Model | Roller | Ring |

Feeding Size (mm) |

Finished Size (mm) |

Mill System Power (KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

|

Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1-3 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8-20 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28 | 11550*9500*10500 |

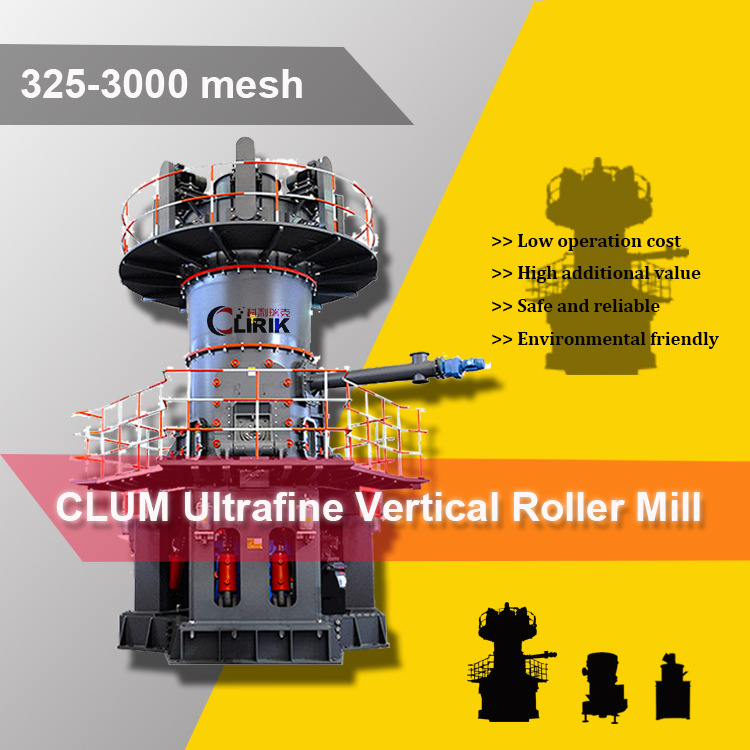

CLUM ultrafine vertical roller mill

CLUM ultrafine vertical roller mill is used for 325-3000 mesh calcium carbonate powder grinding plant

| Main configuration and production | |||

|---|---|---|---|

| Item Model | CLUM1425 | CLUM1632 | CLUM1736 |

| Working Diameters(mm) | 1400 | 1600 | 1700 |

| Number of rollers(pieces) | 3 | 3 | 3 |

| Number of classifier(pieces) | 5 | 7 | 7 |

| Power of classifier(Kw) | 5X15 | 7X15 | 7X(15~18.5) |

| Main unit power (Kw) | 250 | 315 | 355 |

| Blower power(Kw) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

|

Less than 2μm=34% output(t/h) |

11-14 | 13-17 | 15-19 |

|

Less than 2μm=46% output(t/h) |

7-8 | 9-10 | 11-12 |

|

Less than 2μm=60% output(t/h) |

3-4 | / | / |

|

Material: based on calcite Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments |

|||

Uses of various fineness calcium carbonate

200 mesh: additives used in various feeds, calcium content exceeds 55.6, no harmful ingredients.

250 mesh-300 mesh: plastic factory, rubber factory, paint factory, waterproof material factory interior and exterior decoration materials and coatings, the whiteness is greater than 85 degrees.

350 mesh-400 mesh: used in manufacturing, water pipes, chemical industry, whiteness above 93 degrees.

400 mesh-600 mesh: used in toothpaste, soap, whiteness greater than 94 degrees.

800 mesh: used for rubber, plastic, cable, polyvinyl chloride, etc., the whiteness is greater than 94 degrees.

1250 mesh: PVC, PE, paint, coating grade products, papermaking primer, paper glazing, whiteness above 95 degrees.