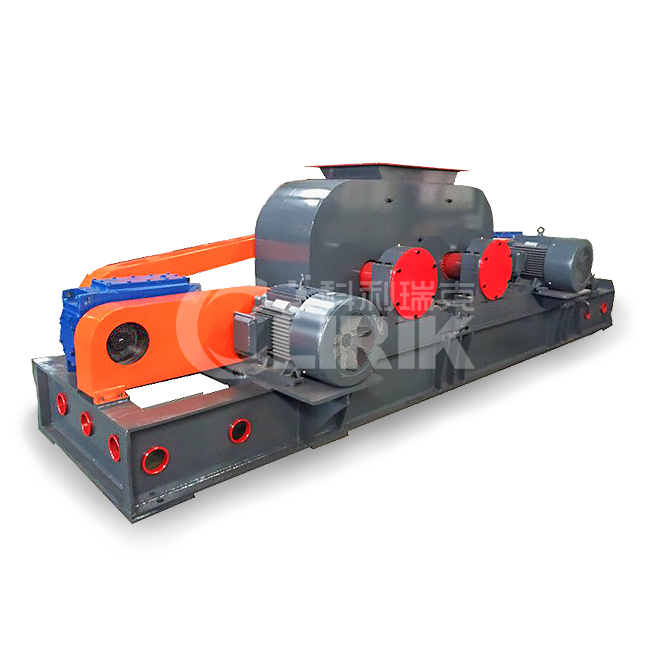

Before barite is applied to various production areas, it needs to be ground. A complete barite powder grinding plant includes crushing equipment, grinding equipment, feeding equipment and conveying equipment, etc. Users can also choose related auxiliary equipment according to production needs.

What is the processing process of the barite powder processing plant?

Barium is an important barium-containing mineral. It has high specific gravity (4.3-4.7), low hardness (3-3.5), stable chemical properties, insoluble in water and acid, and barite can be used as a white pigment (commonly known as Lide Powder), it can also be used in chemical, paper, textile packing and other industrial sectors. The equipment needed to form the production process of barite powder includes electromagnetic vibrating feeder, jaw crusher, barite grinding mill, powder separator The production line has the advantages of strong production capacity, high efficiency, good energy saving and environmental protection performance, long service life, small footprint, etc. The barite material processed by grinding has high application value.

The crystals of barite are large and tubular, and the crystals can sometimes form rose-shaped or bifurcated crystal blocks when gathered together. This is called barite. Pure barite is colorless and transparent, generally white, light yellow, with glass luster. In addition, barite can be used as a white pigment and also used as a filler in chemicals, papermaking, and textiles. The chemical composition of barite is that the crystal belongs to the orthorhombic sulphate mineral. It is often thick plate-like or columnar crystals, mostly dense block or plate-like, granular aggregates.

The milling equipment can choose different types of mills according to the processing needs of customers to produce various powder finenesses to meet the production needs of the industry and help barite powder create market value in various industries. Provide one-to-one product service, and reasonably customize the selection and configuration plan according to the customer's processing needs.

Naturally mined barite materials are sent to the jaw crusher through an electromagnetic vibrating feeder for preliminary crushing. After being crushed by the jaw crusher, the bulk materials are sent to the storage bin by the bucket elevator, waiting Grind. After that, the barite material in the storage bin is sent to the barite grinding mill for grinding operation, and it must be conveyed in continuously and evenly to avoid blockage. After grinding, the barite materials must be blown to the separator for sorting under the action of a blower. Two specifications of barite materials are sorted out, and the materials that meet the requirements are sent to the storage bin through the pipeline. The output of the discharge valve is the finished powder, and the material that does not meet the requirements is re-ground until it is qualified.

Advantages of barite powder grinding plant

1. The production line adopts a continuous working system of dry ball milling and reclassification, and its output is large;

2. The grinding medium and lining board are made of alumina ceramics and silica, which has little pollution to the high-purity processing of materials, and the product has high whiteness, good gloss and stable quality indicators;

3. The equipment is easy to operate, and the whole process is automatically controlled by PLC, which reduces labor intensity and saves production costs;

4. The grading wheel blades are made of polymer wear-resistant ceramics, which not only reduces the pollution of raw materials, but also increases the service life of the grading wheel;

5. The entire system uses high-purity alumina for wear protection, which not only ensures product purity but also prolongs the service life of the equipment;

6. The entire production line is carried out under negative pressure, and dust removal points are reasonably designed to effectively control dust spillage and meet environmental protection requirements.

Why choose the barite grinding plant of CLIRIK Machinery?

1. The structure of the barite grinding production line developed by CLIRIK Machinery is very delicate, and the connection between the equipment is quite compact, so the overall area is small and the operability is strong.

2. High-quality production lines are more likely to be favored by users. CLIRIK Machienry also attaches great importance to the quality of equipment, especially in terms of structural configuration.

3. In the process of purchasing it, users are more concerned about its price. Only a reasonable price can attract attention and stand out in the fierce market competition, and its sales can also be greatly improved in this process.

4. The new generation of barite powder production line also has the advantages of energy saving and environmental protection, and the energy consumption is greatly reduced. In this process, the noise has also been effectively controlled, and the user's recognition of this is quite large.

Two points need to be paid attention to when buy barite processsing plant

With the popularization of barite grinding technology, more and more people invest in the barite milling market, and more and more manufacturers have begun to produce barite milling equipment, and have the ability to set up barite milling production lines. More and more, users should keep in mind the following two points in addition to the production scale, production efficiency, particle size of the finished product, and the amount of production maintenance when purchasing a barite grinding production line:

1. The manufacturer's delivery speed must be fast

The delivery speed of a manufacturer shows the work efficiency and integrity of a manufacturer. The delivery speed of a manufacturer not only directly affects the user’s production income, but also affects the manufacturer’s own interests. If the manufacturer promises to deliver on time, it will be due to various reasons. Delaying the delivery time will result in the loss of some customers. Each user has his own production plan. If the production target is not completed within the budget period due to the delay in the equipment shipment, additional costs are required, which is obviously not what the user wants to see. Therefore, users must choose fast delivery when choosing the manufacturer of the barite grinding production line, and pay special attention to the delivery time when signing the contract with the manufacturer.

2. The manufacturer must have a strong ability to design and produce plans

The barite powder processing plant needs to be customized, that is, the manufacturer should customize the production line for the user according to the user's existing production conditions, production requirements and expected production goals. If manufacturers have stronger design capabilities, they can formulate a variety of production plans for them according to the different production requirements of users. The barite grinding plant requires a combination of multiple equipment, and each equipment can only achieve the ideal production effect if it is properly coordinated. Shanghai Clirik Machinery Co., Ltd. specializes in the production of barite grinding equipment. The company promises to configure an economical and reasonable grinding production line for every user in need. The company's commitment is not only considering the user's economic benefits , It is directly related to our own interests.

If you need a high-quality, low-price, long-life barite powder processing plant, please call CLIRIK Machinery, we will tailor it for you with a more professional vision, to ensure that the production line creates a more generous return on value for you , Looking forward to your visit!

Email: sales@clirik.com

WhatsApp: 008613917147829/ 008613512155195