Gypsum powder making production line, Gypsum powder processing plant

Gypsum powder application

Gypsum powder is one of the five top gel materials, which occupies an important role in the national economy. It is widely used in construction, building materials, industrial mold and Art model, the chemical industry and agriculture, food processing and pharmaceutical cosmetic and many other applications. With the rapid development of the economy and the emphasis on environmental protection in recent years, the power plant desulfurization has become an important part to produce gypsum powder, in addition to citric acid gypsum, fluorine gypsum, salt, gypsum and chemical gypsum, relying on the rich natural and human resources to carry out the comprehensive utilization, the development of gypsum industry is the construction of a recycling economy needs more new highlight for many investors.

How to make gypsum powder

Raw material: natural gypsum ore, gypsum, phosphogypsum) project of building gypsum powder production line process is divided into four steps:

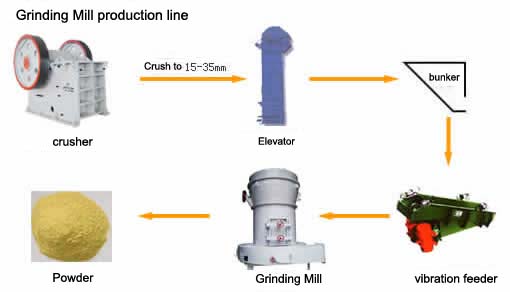

(1) Crushing process

(2) Pre-grinding process

(3) Calcining process

(4) Storage and transport process

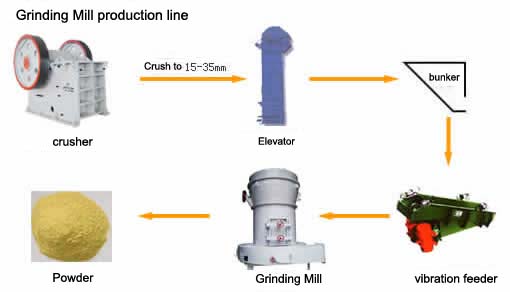

In the gypsum powder grinding plant, gypsum grinding equipment is used for gypsum pulverizing to produce gypsum powder from crushed gypsum rock. CLIRIK Machinery can supply the state-of-the-art manufacturing facility which is fitted for gypsum grinding process, to produce a wide range of micron size of chemical purity, outstanding brightness and controlled particle size distribution.

Gypsum powder making production line

In the gypsum powder making production line, a series of continuous production equipment are used for produce production drilling. 1.3 tons of ore storage and selection of gypsum can produce about one ton of gypsum powder gypsum in the calcinations process. Gypsum is shipped from stope site to storage and selection site. Through storage to resolve two issues: a guarantee continuous production, will not be discontinued because the raw moment supply is not enough; the two is that by storage manually sorting, we can ensure the quality of the product, to produce qualified products.

Crushing process usually has to process two stages to ensure the gypsum stone is suitable for calcinations process. A primary ore crusher crush gypsum stone into smaller particles, and the general control of particle size is less than 8cm, and after screening, the larger particles will have a re-crushing, and the smaller particles will be convey by the belt conveyor into the secondary crushing with a hammer crusher machine to control the particle diameter less than 2 cm, and then transfer by the bucket elevator into the rotary kiln calcination. Calcined calcination process is the main process of the production of gypsum powder in a rotary kiln.

Gypsum powder processing equipment plant

>> Jaw crusher: output fineness 10-105mm, capacity 90t/h

>> Hammer crusher: output fineness smaller than 25mm, capacity 45t/h

>> Box-type crusher: input fineness 600-800mm, output fineness smaller than 50mm, capacity 160t/h

>> European coarse powder mill: output size below 3mm, capacity 100t/h

>> YGM high pressure suspension Raymond mill: output size between 15-425meshes

>> HGM three-ring micro powder grinding mill: output size between 200-3000meshes (can be adjusted)

If you have any questions about Gypsum powder processing equipment plant please do not hesitate to contact us.

Phone: 0086-21-20236178

Contact person:Jessie Zhao

E-mail: jessiezhao2013@hotmail.com